5 years ago, I posted to TT.net to release the Dual MAF Translator to our community. It was a leap of faith and you guys have shown a fantastic amount of support, for which I'm very grateful. I'm excited again today to announce the release of the 2nd generation of this product which brings together lessons learned to offer a more functional, reliable, flexible, and better built product.

(Inventory is available from most major vendors starting today 10/10/2014)

Subharnesses - A New Wiring Approach

The 2nd gen translator continues to offer digital precision, true dual air intake metering and easy plug and play installation... a combination that has proven to be a popular way to enable the power potential of dual intake paths with any intake hardware choice.

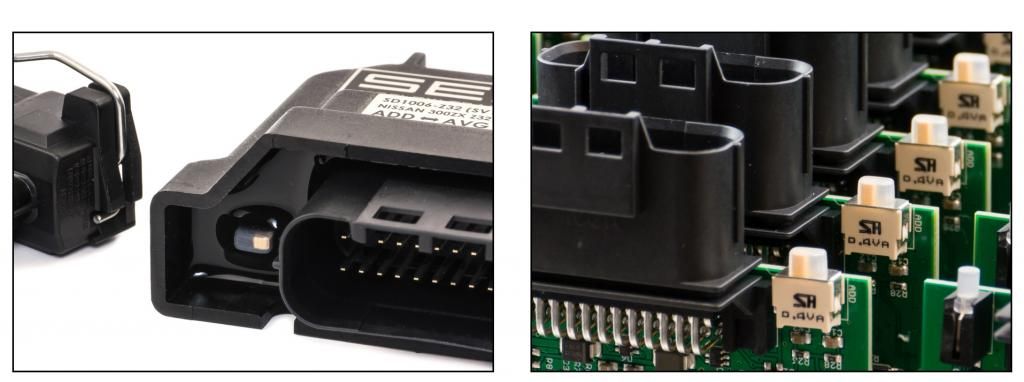

The new unit departs from thru-wall case wiring, instead opting for an ECU style 23 pin harness connection point. This serves a number of purposes. First, the subharness approach produces wiring that is far more robust with enhanced fit and finish. Second, it allows the owner to purchase a standard length unit and later upgrade to an extended subharness or to any future subharness options.

Laid out like a small ECU, the translator was carefully designed using industry practices.

The entire assembly below shows the removable standard subharness and the new reversible bracket.

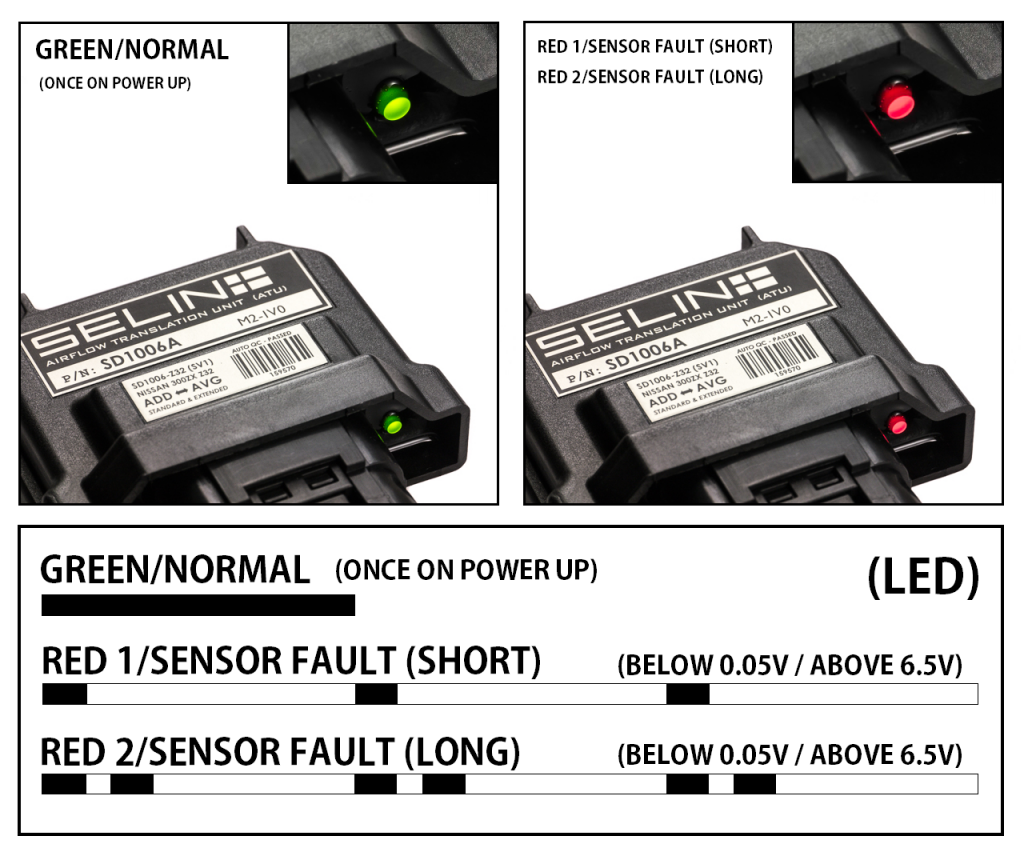

The LED Status Light

The bi-color LED light was added to provide valuable information about the health of your sensors, wiring, and translator unit. In normal operating conditions a green light will display for exactly 3 seconds after power on. This indicates that two sensors are present, providing voltage within their operating range, and the wiring to the control unit is fault free. By default, both the green and the red light indicate that the translator itself is functioning properly. Should it fail to properly operate, no lights will illuminate. Both red fault codes (1&2) then only apply to sensors and harnesses. Once triggered, the red codes will display until the unit is restarted. The lights are informational only and do not alter the calculations within the unit. The graphic below illustrates the lighting patterns for different conditions.

Enhanced Waterproofness

On the original translator, connector boots were chosen per the Bosch standards that spanned through the early 80's to the early 90's. Individual wire seals were not attempted then because of shorter warranties combined with the costs of the precision needed to form finer assemblies. Later on manufacturers adopted the single wire seal approach which provided significantly higher weather resistance and thus longer service lives. Although not authentic to the era in which the Z32 was built, the move to this harness style was the right choice. Many new replacement parts from the dealer are coming this way now and it's a move in the right direction.

The dip switch is now fully sealed with a conformal silicone boot that protrudes through the urethane potting resin. As before, it selects ADD or AVG programming with the direction indicated on the serial number label above.

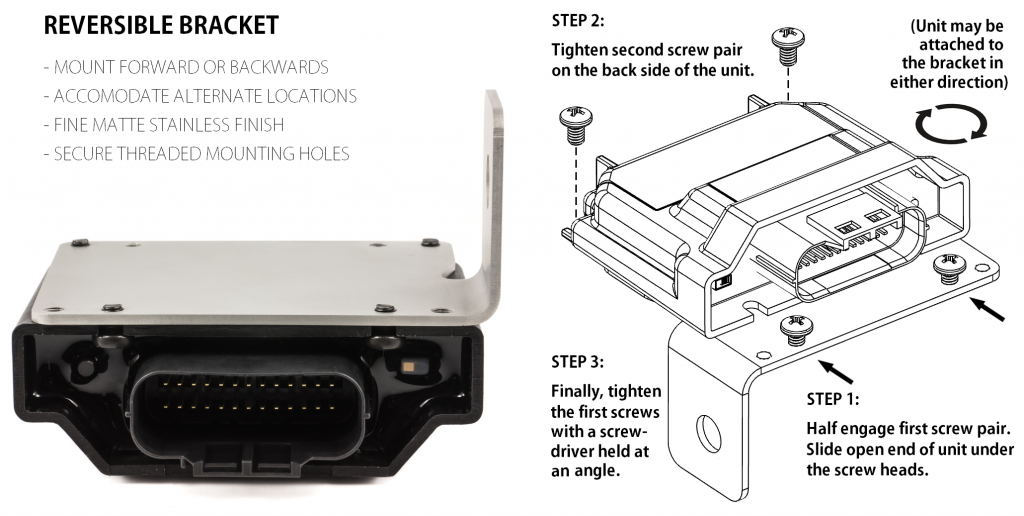

Versatile Mounting

Fully immune to interference

The first version went through a number of changes to address the threat of conducted and RF power from high frequency HID ballasts. The ultimate rock solid solution was the implementation of a watchdog timer and a high speed startup capability. Starting in 2012, units labeled "WD1" could reset themselves in less than the time between cylinder firings. This fix has been proven flawless since. The 2nd gen unit carries on this functionality and is thus also fully immune to the electrical environment.

Factory Reprogrammability

The removable connector provides a fully encrypted entry point for factory reprogramming units to future firmware versions that can include added functionality or other enhancements. I should emphasize that this is factory reprogramming and updates would require shipping if needed. How this would be handled needs to be worked out in the future but the functionality is there now.

Plans for the future... blowthrough mass air!

The thought of implementing a blow through sensor arrangement was running through my head before the first translator design ever made it to silicon. With careful calibration, blow through mass air metering can be very accurate and repeatable. For blow through applications others in the aftermarket have found that the blade style Hitachi sensors widely adopted by Ford produce fantastic results and are long term stable and reliable.

In a collaboration between Selin Design and Ashspec, a blowthrough mass air metering system was developed for placement in the 2.5" Ashspec intercooler pipes just aft of the intercoolers. In this collaboration, the sensors were calibrated for the translator instead of the translator to the sensors. The result is compatibility with 2nd Gen translators sold from today onwards with the eventual release of these sensors. An extended subharness with the appropriate connectors will be available through my new site. Ashspec is producing sensor housing that swap cleanly into their 2.5" piping system as well as the OEM pipes with appropriate adaptors. The release of this option was supposed to coincide with the 2nd gen release however work in this area is ongoing. The exact timeline is TBD but it is definitely upcoming.

But there's no need to wait... today's inventory is future proof! Enjoy dual intake power and add a blowthrough kit when you and the product are ready.

Ash had been running the blowthrough hardware pictured below without incident since mid 2013 and report fantastic drivability and an overall positive review.

Thanks! Visit the new website to see more product details and photos.

www.selindesign.net

www.selindesign.net